For the simplicity that lies this side of complexity, I would not give a fig, but for the simplicity that lies on the other side of complexity, I would give my life.

– Oliver Wendell Holmes

This article series is written for those who are interested in the why, how, and what related to moving towards a circular economy, especially in the fields of business and technology.

Circular Analytics

The main purpose of data analytics and the tracking of metrics is to regularly check to make sure that we are progressing along our intended path. It is not difficult to lie with data and statistics but it is much easier to lie without it. Sometimes, measuring gives the illusion that you’re achieving something. In this case, and perhaps in all cases of tracking metrics, we want to measure what matters so that we are clear on how to progress towards what we want to achieve, in order to actually change. Enough pep talk. How do we then leverage data analytics and specifically business intelligence to track our progress along the path towards circularity?

Three Dimensions of Circular Metrics

In Part 1 we laid out the model which consisted of the three dimensions of circularity: recirculation, utilisation, and endurance. What are useful metrics that track these three dimensions? Before we start looking at metrics I must raise a warning finger:

The Circular Economy faces a dilemma. An organisation interested in reporting and improving the circularity of its product or service can choose from a growing array of circularity assessment tools. Some organisations may even feel compelled to develop their own. The challenge, of course, is that the concept of circularity may lose its power to stimulate societal-scale change if firms, public agencies, and other organisations choose to define and measure circularity in the manner that is most convenient to themselves, and inconsistent with/contradictory to everyone else.

In the best of worlds, you bring questions to this article and I provide answers. Unfortunately, we’ve moved beyond the naive realm of simple answers to difficult questions. However, I can provide you with suggestions, tools, and the ability to become better at asking the right questions. Here are some useful thoughts related to measuring recirculation in different industries and businesses:

Metrics of Recirculation

- How much of a product’s material comes from a prior use phase or returns to another use phase?

- How much of what isn’t your end product provides value? In physical manufacturing this might be utilising or selling waste material

- How much of your material is newly extracted virgin material compared with recycled or re-used material?

- A recirculation metric developed by RISE: The economic value of a product’s recirculated material (both input and waste) divided by its total economic value. The outcome is a single value, between 0 and 1, where a score of 1 represents a product whose value comes entirely from recirculated material.

- Recycled material in-flow percentage, defined as the amount/mass of recycled material used in production divided by the amount/mass of total material used.

- Product recyclability percentage, defined as the amount/mass of recyclable material divided by the amount/mass of total material in the product.

- Same as the in-flow and out-flow above but instead of looking at amount/mass you look at economic value.

- How much of your water use consists of reused water? How much of the used water can be reused afterwards? Are you tracking water use at all?

- How much of your energy waste is being reused, for example for heating?

- How much of your software is designed with modularity and re-use in mind?

- How much of the material used in your business can be recirculated, recycled, or re-used?

- What are the different end-of-life scenarios of your products/services (EoL)?

- How is the potential for recirculation distributed in scale? Recirculating entire products, their parts and components, their raw materials, their incinerated waste?

- How much of your waste (products, unused services, components, parts, materials) is currently being recirculated within your business?

- How much of your waste (products, unused services, components, parts, materials) is currently being recirculated to external actors?

- How much of your waste is deemed impossible to recirculate?

- How much time and resources does your business currently spend on recirculation processes?

Metrics of Utilisation

- How often are your products/services used and by how many? What is distribution of frequencies of use, namely what percentage of products/services are being used every hour, every day, every week, every month, etc?

- What is the change in economic value due to the product being used? Does its value increase the more users there are? Does it decline with each user?

- How many services/products do you rent compared to directly buying?

- Can your products be repaired if broken? Who can repair them?

- What percentage of cloud services are actively being used each day, week, month? What about analytics dashboards and databases? How many users are there?

- How much of the data you collect is being actively used for anything? Be honest.

- How many products/services you create can be maintained directly by its users? How many require your constant management?

- How much computation is currently occurring in environments whose services aren’t in use?

Metrics of Endurance

- For how long do you estimate that a certain product/service will be in active use? What is the average estimate across your organisation? Do you believe anything you build will usefully last a year? Ten years? A hundred?

- The Market Endurance-metric developed by RISE aims to represent the ability of a utility to retain its value by estimating the cost of keeping a utility’s market value over time.

- What is the average timespan a product/service is being used? How are your different products/services distributed around this average? Are some being used for a very long time where others are used for a short time or do most fall close to the average?

- How long are your products/services in use? How does it compare to alternative products/services?

- How does the economic value change over time?

- How repairable is the product/service? Does it break completely or does it wear down?

- Do you have estimates for how long a product/service should last?

Three Dimensions, Three Key Indicators

To get slightly more concrete and technical, let’s look at selecting one metric for each dimension. RISE has done a lot of work for us here so we’ll select their recirculation metric (C), utilisation metric (U), and (market) endurance metric (ME). They are defined as follows:

C = E_R / E_T

Where:

E_R = Economic value of recirculated material or resources

E_T = Total economic value

C = The recirculation metric which you want to have as close to 1 (or 100%) as possible, which means the full value of the product is recirculated.

U = T_a / T_p

Where:

T_a = Actual active lifespan (cycles, hours, etc)

T_p = Potential maximum lifespan (cycles, hours, etc)

U = The utilisation metric which you want to have as close to 1 (or 100%) as possible, which means the product’s actual lifespan equals the max potential lifespan

ME = 1 – (C_T(t) / V_T(t))

Where:

C_T = L+R

where:

L = Total loop cost, or the allocated cost of maintaining and repairing the product delivering the utility

R = Total (re)placement cost, or the allocated cost of placing the product as utility carrier on the market or replacing it with a core unit (or core components) that ensure a retained market value in the future

V_T = The total allocated revenue of the utility, measured at sales price t_* = A time period that is at least long enough to include the replacement of all a product’s original components

ME = The (market) endurance metric which you want to have as close to 1 as possible, which means the product continues to generate value at a low cost, in other words meaning it lasts, in a sense, ”on its own”

One option is to further sum these three metrics into a circularity index between 0 and 3, 3 being the best and most circular and 0 being the least circular.

If you can calculate these metrics and follow up on how they change regularly, you’re further along the path towards circularity than most companies.

Every step counts

Hopefully, some of the points above give you enough to start measuring something. An important addition is that the above focuses only, simplistically, on circularity. You might therefore notice that there is no explicit mention of social or environmental sustainability, total energy consumption, or overall quantified impacts on climate. This is intentional. All of these are of course crucial to include in your business, but not when analysing and measuring circularity. The path towards circularity is just one path on the landmass that is sustainability and it is important to be able to, at times, focus on singular aspects of the problem. It often becomes easier to tackle that way. For now, embrace the mess. I’d rather have you take a single step in the right direction than a million steps in the wrong one.

In the next article, Circularity Part 3: Circular Actions, we will look at possible actions of circularity.

Written by David Janzi, data engineer at Stretch Beyond

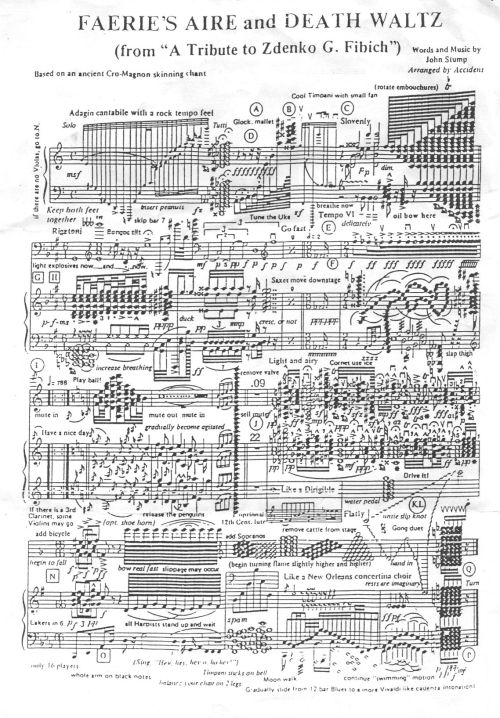

Image by John Stump